Thermal Spray Coatings

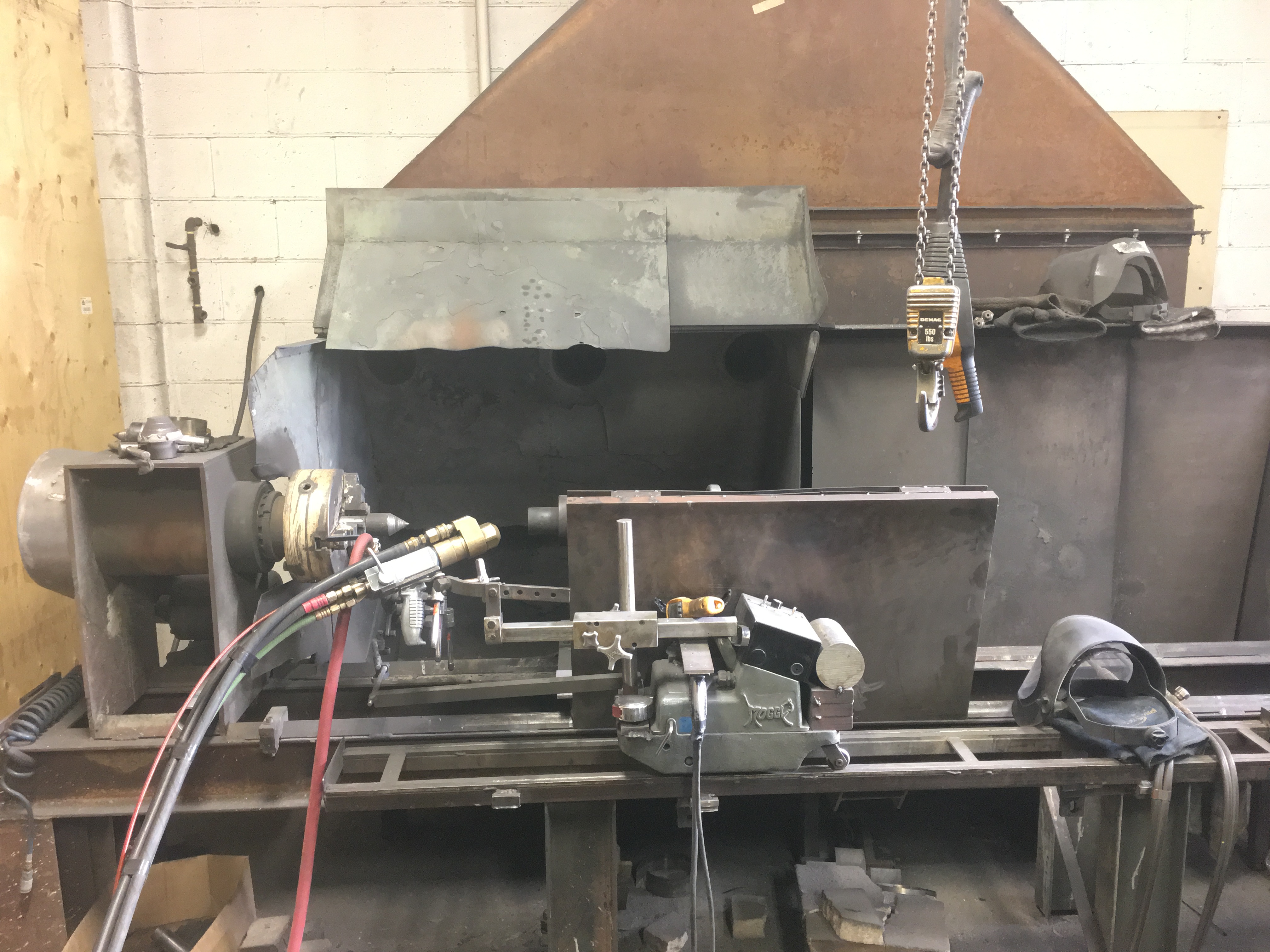

HVOF System: High Velocity Oxygen Fuel Thermal Spray

HVOF coatings fight corrosion by enhancing the surface consistency, hardness and bond strength. HVOF coatings provide durability in harsh service conditions, as well as prevent wear and corrosion for applications. These coatings increase the components service life and they provide a smooth surface. Tungsten Carbide is sprayed with a HVOF gun and ground down with a diamond stone on our cylindrical grinders.

Benefits

- Improved toughness and excellent wear resistance

- Low compressive stress, which can result to thick coatings

- High density

- Bond strength

- Optimum hardness and corrosion resistance

- Beneficial residual stress and fine surface finishes

- Mainly used for Tungsten Carbide